Experimental facility for thermal-hydraulic investigation of heat exchange devices at medium temperatures(> 100oC)

This experimental facility is being used for the thermal-hydraulic characterization on a laboratory scale of heat exchange (removal)

devices intended for receivers of concentrating solar systems.

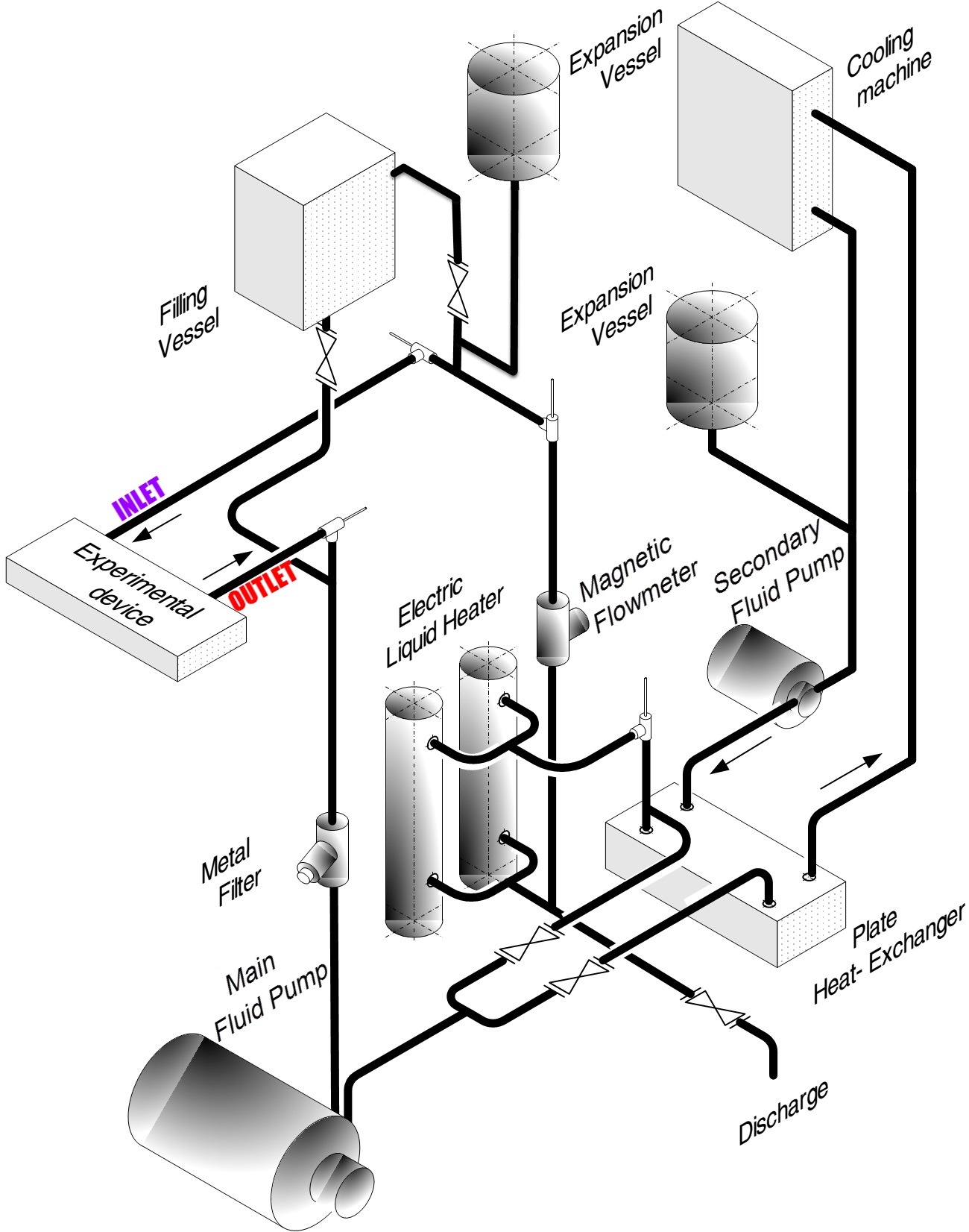

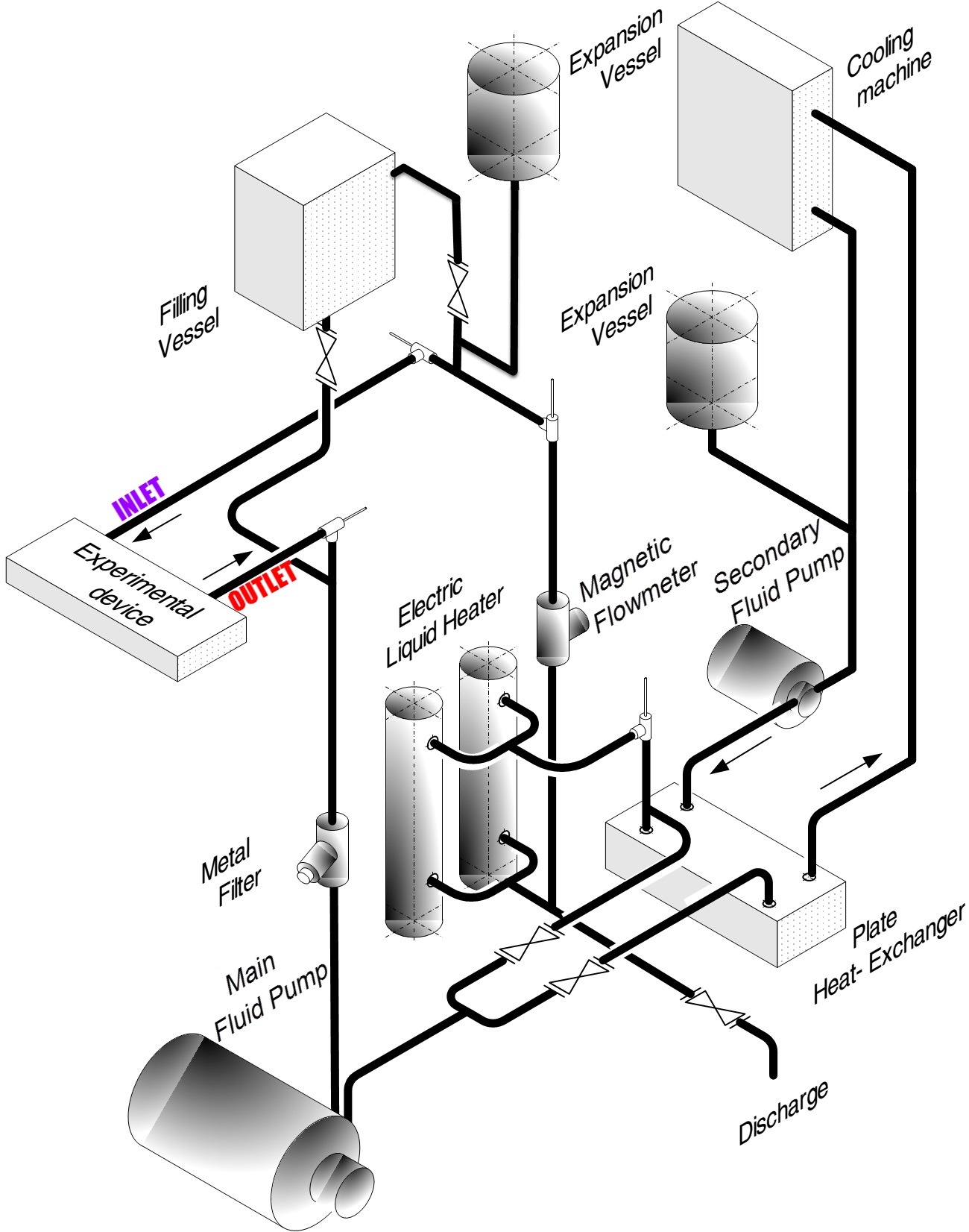

The facility comprises a hydraulic heating-cooling loop, whereby heating of the devices being tested (specimens) is achieved by means of specially constructed heating elements attached to them.

These are metallic plates of 1 meter length, integrated with electrical resistances in the form of thin cylindrical rods. The working (heat transfer) fluid is a synthetic oil (e.g. Therminol SP),

suitable for the temperature range -10 oC to 315 oC.

The thermal-hydraulic loop of the facility consists of the following individual subsystems (see figures):

- The supply tank, which contains the heat transfer fluid

- The expansion vessel, for the expansion of the working fluid

- Pump of the ‘regenerative turbine’ type (Speck NPY 2251 MK-TOE), suitable for operation at elevated temperatures (up to 350 oC)

- The secondary cooling loop, which is itself composed of:

- An internal plate heat-exchanger, mounted on the stand where heat exchange between the return hot fluid from the device and the coolant (water) of the secondary loop takes place

- Piping and expansion vessel

- External liquid-air heat exchanger, where cooling of the coolant (water) of the secondary loop takes place before its return to the plate heat-exchanger in order for a new cooling cycle to start.

- The electric heaters (electric resistances), which heat the working fluid (Therminol SP) up to the desired inlet temperature for the heat removal devices

- The magnetic flowmeter (Icenta IC-LPM 050B-H), which is suitable for operation at elevated temperatures (up to 350 oC)

- The piping and necessary valves for the proper operation of the loop

- The central monitoring board, with the process controllers and other electrical subsystems (inverter, fuses etc.).

The connection of the thermal-hydraulic loop described above with the device specimens under testing is achieved by means of suitable flexible metallic hoses (Flex AISI 316 L) capable of withstanding high temperatures (up to 650 oC).

|