MECHANICAL/SOLAR - ASSISTED DRYING PROCESSES AND SYSTEMS

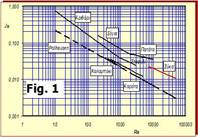

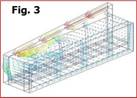

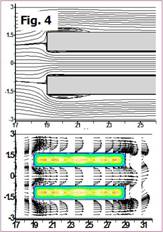

Research in this field focuses on the analysis of heat and mass transport phenomena, the investigation of optimal drying conditions for various agricultural products

(drying curves) and the development of drying process models aiming at the optimal design of hot air mechanical dryers.

Both experimental methods and numerical simulation are employed and the main activities so far comprised :

Numerical Simulation

|