Phase Change Materials (PCM)

• Store energy as latent heat of fusion

• This is recovered during subsequent material solidifcation

• Advantages of PCM: large storage capacity, thus smaller tank volume for the same amount of stored energy

Storage media under investigation (melting point):

D-Μannitol (165°C), Erythritol (120°C), Dimethyl terephthalate (142°C)

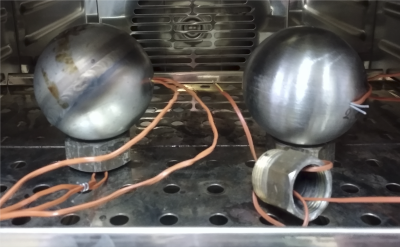

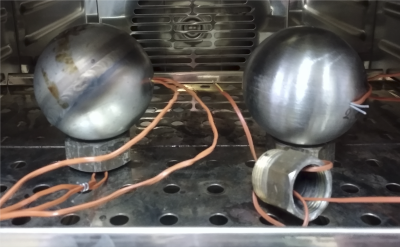

Storage Medium (PCM) In Encapsulated Form

• Specially designed spherical capsules with metal shell (steel)

• Thermocouples at different positions in the interior for temperature monitoring

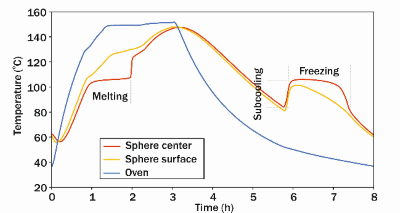

Experimental investigation

• Thermal cycling trials inside an oven for testing the durability-tightness of capsules and stability of PCM thermophysical properties : melting/solidification point, latent heat of fusion, degree of subcooling, thermal capacity, thermal conductivity

• Use of reference material for estimating the capsule external heat transfer coefficient (T-history method)