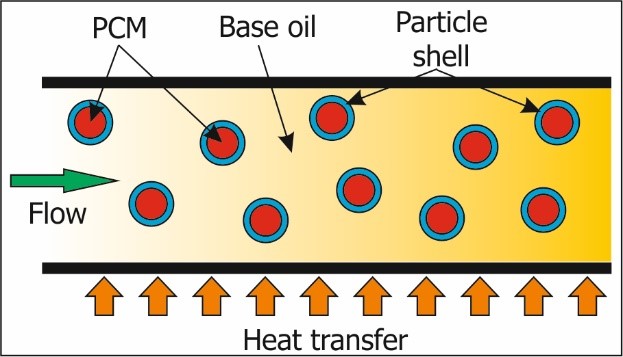

For more than two decades, one of the key areas of research interest in thermal engineering has been the development of new, advanced working fluids by adding solid particles to a liquid (base fluid). These particles, composed of solid material that may or may not undergo a phase change, aim to enhance heat transfer in relevant systems (such as heat exchangers, cooling or air conditioning installations, and thermal management systems for electronic equipment) by increasing both the thermal conductivity and specific heat capacity of the base fluid. When the added particles are made of phase change material (PCM), the fluid serves not only as a heat transfer medium but also as a thermal energy storage medium. To improve the performance of such particles, it is necessary to encapsulate them within an appropriate shell. Since, in their most widespread form, these particles were initially of micrometer size, the resulting fluids were termed "micro-encapsulated phase change material slurry" (MCPS). Encapsulation of PCM addresses various challenges associated with their use, such as corrosion of metallic surfaces, material degradation, subcooling, and dissolution of PCM into the base fluid. Additionally, this approach provides a large heat exchange surface area, ensuring both heat absorption and release under stable temperature conditions. Furthermore, when the dispersed particles are on the nanoscale, the term NEPCM (Nano-encapsulated PCM) is used, while the resulting fluid is referred to as a slurry. By dispersing nanoparticles into the base fluid (carrier fluid), they can circulate through pumps and pipelines in thermo-hydraulic installations, facilitating heat transfer and storage, as illustrated in the schematic below.

The Solar & Other Energy Systems Laboratory (SESL) of the National Center for Scientific Research "D" has launched relevant activities for the utilization of such fluids in concentrated solar systems. Originally, flows of nanofluids based on single-phase, metallic particles in a parabolic-trough solar collector has been studied by numerical simulations. Subsequent research focused on the synthesis of fluids based on micro-encpasulated phase-change materials (MEPCM), in cooperation with a specialized laboratory from abroad. Results of those first activities have appeared in the following publications :

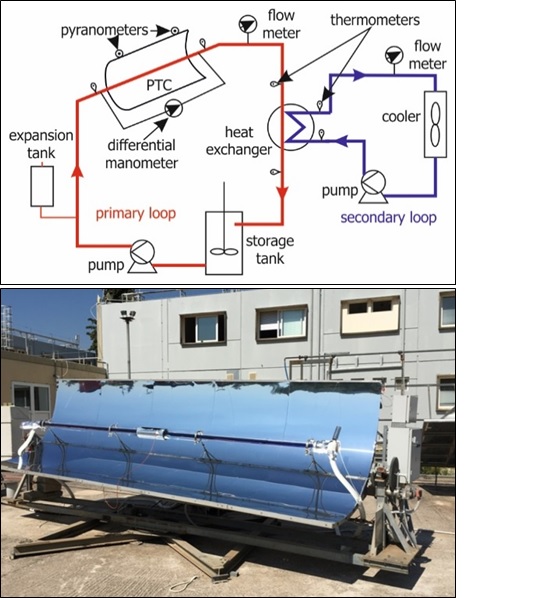

The designed setup involves heating oil through a parabolic solar collector and consists of two separate circuits connected via a heat exchanger. In the primary circuit (red), the main components are the solar collector and the storage/mixing tank, while the secondary circuit (blue) contains the cooling unit, which represents a thermal load (i.e., the consumption of thermal energy). Heat is transferred from the solar collector to the working fluid (e.g., base oil or NEPCM slurry), then passed through the heat exchanger to the secondary circuit, and finally dissipated into the environment via the air-oil cooler. Potentially, the same or different fluids could be used in both circuits, and determining which option is more effective remains a subject of investigation. However, the primary study of NEPCM slurry mainly takes place in the primary circuit, focusing on its potential to enhance collector efficiency. The secondary circuit is used to regulate thermal loads in the primary circuit and dissipate the solar heat absorbed by the collector. If needed, a "receiver test sample" identical to the solar collector’s receiver can be used instead, to avoid challenges associated with the actual receiver (such as uncontrolled solar energy input and uneven heat transfer).